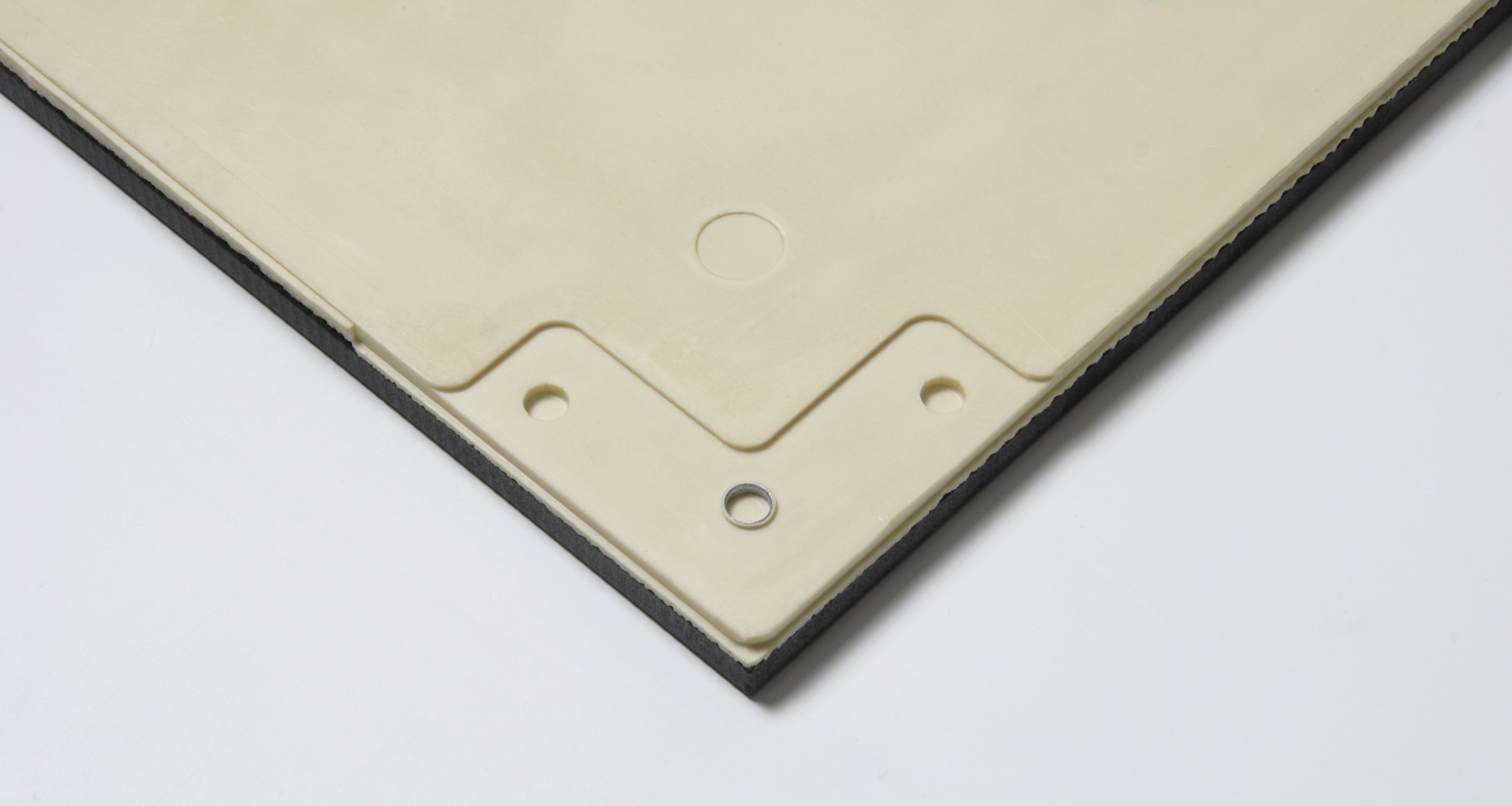

The base plate.

The innovative base plate is the result of a special foaming process that allows for customized surface coating. This process allows modulea to be produced with surface materials of varying thickness at a uniform height, eliminating the need for complex leveling of the substrate when using different coverings. The recesses integrated on the back are designed to hold the installation cross which ensures precise and stable laying. They also allow the plateto make full contact with the floor. The robust construction and the special manufacturing process make the base plate ideal for highest loads.

The advantages of modulea’s foam core speak for themselves:

- it gives the flooring elasticity

- it offers dimensional stability

- it is lightweight

- it is temperature resistant down to -30° and up to +80° Celsius

- it has a long lifespan

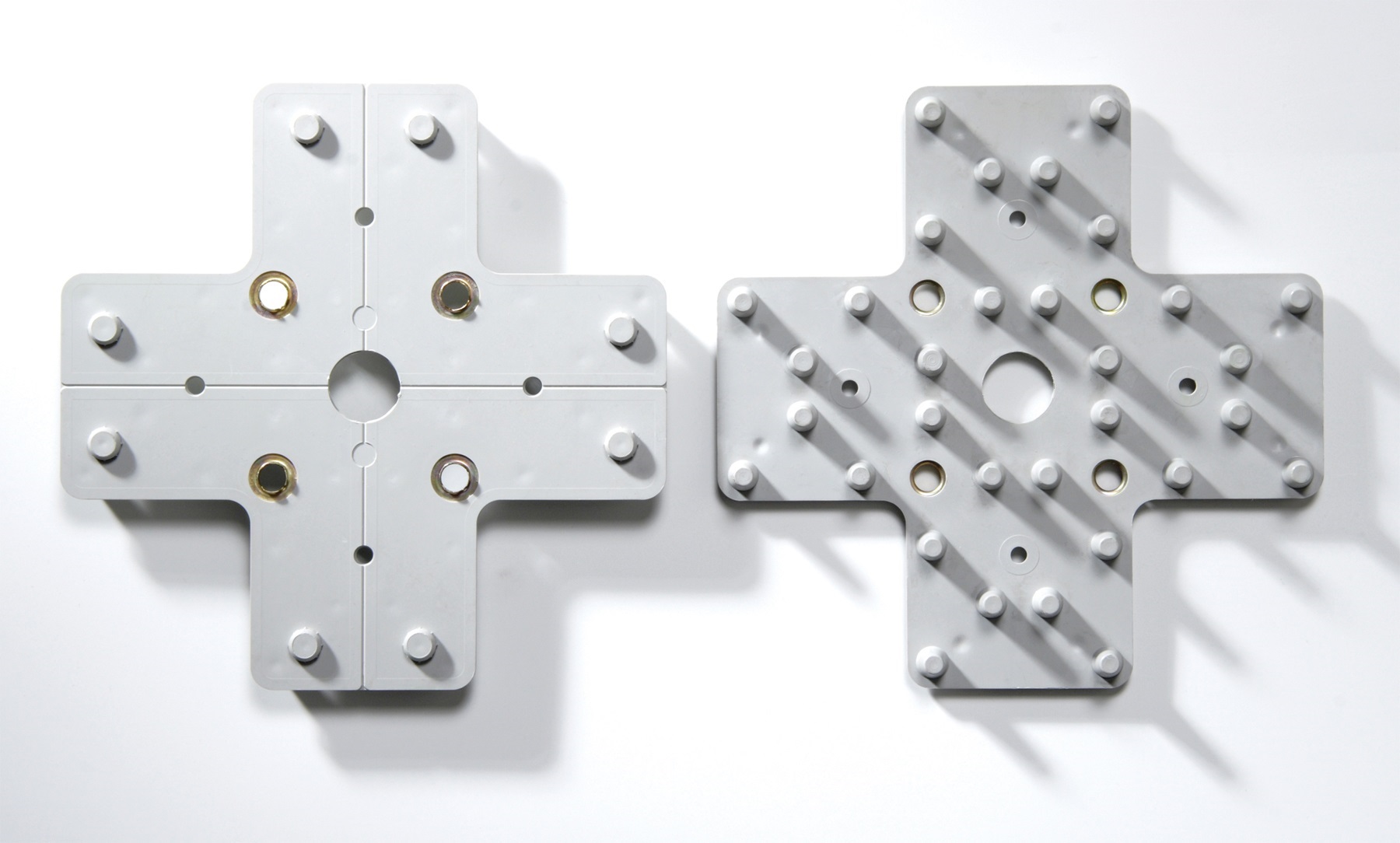

The corner-mounted installation cross is equipped with specially designed knobs and ensures precise and quick installation of the base plate. This allows the individual plate to fit together to form a stable, uniform structure. Once the first plate has been laid, all the others can be effortlessly inserted and, if necessary, removed individually. This offers maximum flexibility, for example for the subsequent installation of floor tanks or for adjustments when modifying the room for events.